Wednesday, May 14, 2008

Competition Results

80 100 100 25.5 50.5 2.1* Blue Hills 358.1 1st Place, 1st Mission

88 70 100 38 54.5 NYCHEA 350.5 2nd Place, 1st Poster

84 90 100 27.5 40.0 Milton 341.5 3rd Place

74 70 100 25 30.5 Diman 299.5 Judge's Choice

92 50 100 18.5 38.6 Rogers 299.1 1st Engineering Eval

82 20 95 23 46.2 MAST 1 Deception 266.2

71 0 100 24 40.0 CRLS 235.0 Sharkpedo

86 0 0 32.5 60.5** MATES 179.0 1st Tech Report

62 40 0 18.5 47.8 BMC Durfee 168.3

56 40 0 18 51.3 SE Vo-Tech 165.3

73 30 0 23 39.0 Bristol CC 165.0

84 0 0 22.5 46.7 MAST 2 Autobot 153.2 Guts & Glory

66 0 0 24 52.0 Sound School 142.0

69 0 0 18 39.9 Weaver 126.9 Team Spirit

100 100 100 40 60.0 10.0 410.0 (TOTAL POSSIBLE)

* 2.1 points for pool time bonus

** 0.5 bonus points after average

Final Testing of the Rov Arm

Initial testing was done in the small pool in the systems lab, as well as out of water. A shortened tether was attached to the arm and all functions of the arm were tested. At this point everything worked as planned. The arm was able to pick up five pounds of weight and hold it with no issues.

After the Rov was completely assembled the final tether was filled and attached to the arm. The arm was then submerged in the pool. With the new tether attached the arm opened and closed much slower, but with the same force. The arm was able to grip a rock underwater and hold onto it as it was pulled out of the pool. The arm was also able to grab onto small waffle balls with weights inside that were close in size to the rock crabs. Further testing was done after minor modifications were made to the design. After boring out the syringe holes to a larger diameter the system operated at nearly twice the speed.

While obtaining the temperature, a readout of 54 degrees Celsius was shown. This was within 2 degrees Celsius of the actual temperature and 100 points were awarded to our team. The thermometer setup had a quick response time and showed the temperature within one second of being placed over the vent. When grabbing the rock crabs one crab was obtained and brought to the surface for 20 points. Five points were later deducted for pulling on the tether. Pulling on the tether had nothing to do with the arm and was necessary as the craft was not moving due to the propulsion system. On the second attempt to capture a rock crab the hydraulic control syringe at the top of the pool broke. Too much pressure was applied while lifting the first crab and the arm locked into place. When trying to reset the arm the rubber seal separated from the plastic plunger, breaking the vacuum seal of the system. This prevented our team from capturing another crab, although we only had two minutes left at this point.

Our team ended up placing 6th out of 14 teams. The total score can be seen on the attached sheet. Shown below in Figure 1 is our Rov completing a task during the competition.

Wednesday, May 7, 2008

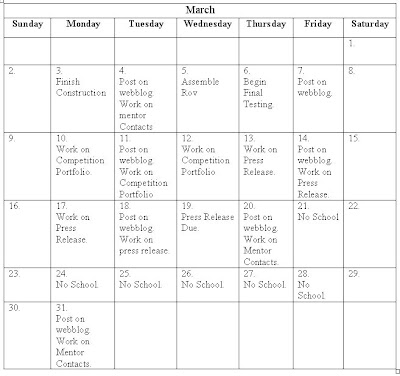

Calendar MP 4

5. Work on testing paper

6. Work on testing paper

7. Finish Calendar and testing paper

8. Begin Self Evaluation

9. Work on Self Evaluation

12. Work on Self Evaluation

13. Work on Self Evaluation

14. Work on Self Evaluation

15. Work on Self Evaluation

16. Finish Self Evaluation

19. Prepare for Final Presentation

20. Prepare for Final Presentation

21. Party

22. Presentation Night.

Monday, March 31, 2008

Press Release

Announcement of Project Progress

Math, Science and Technology Application

Contact: Jeremy Kuhn

Period 7/8

FOR IMMEDIATE RELEASE

March 14, 2008

Systems Engineering II: Rov Team Arm Design

Sandy Hook, NJ, March 14, 2008-

Jeremy Kuhn is a student at the Marine Academy of Science and Technology on Sandy Hook, NJ. He is in the Systems Engineering II class, period 7/8. For Jeremy’s senior project he is designing and constructing a robotic arm for the Mates competition at Buzzards Bay, Massachusetts. This project began approximately January 1st, 2007, when the decision to work on this team event was finalized. Since then much work has been accomplished which is leading up to the competition. Recent progress made on this project includes construction and testing.

Introduction

For the Senior Design Project Jeremy has designed and constructed a robotic arm. This will be mounted upon his teams Rov, which will compete in the MATES competition on April 26, 2008. This competition has taken place for many years and encourages students to learn about possible careers in the marine industry. This year’s regional competition will have 18 teams, where the winner will go on to San Diego to compete in nationals. So far the majority of construction has been completed, and testing has already begun. The final steps of construction cannot be completed until all team members are ready to do so, which should be before March 20th.

Research:

This project began with extensive research. Jeremy began by traveling to the 2007 competition to get an idea of what he would be doing. Over the 2007 summer he came up with four basic designs which would later become his alternate solutions. Two of these designs were powered by hydraulics and two were powered by electricity. After discussing his ideas with his mentor, Jeremy was able to come up with the final solution. This solution has a large, narrow design and is powered by hydraulics. The hydraulics frees the arm from the electrical restraints of the competition. The arm was constructed out of polycarbonate, a very strong plastic which is used in items such as safety glasses and bullet proof glass. The hydraulic components, syringes of varying sizes, were obtained from a local pharmacy. The rest of the components were available within the schools shop.

Construction:

Once the polycarbonate sheeting was delivered, construction started to go very smoothly. Jeremy began by cutting out the four 12” by 1” by ½” pieces for the arms, and the two 6” by 1” by ½” pieces for the mounting blocks. He was able to do this very easily on the band saw. Next Jeremy glued the arms together using epoxy and allowed them to sit. Both arms lined up very nicely showed no major errors. After the glue had dried he cut the ½” by 2” triangles off of the corners. Jeremy then had to sand these areas so that they lined up together when the arm is closed. Before he could begin assembly, Jeremy still had to drill the holes through the polycarbonate. This step can be seen in Figure 1 below.

Figure 1, Main arm being drilled.

Jeremy was not sure if this would go smoothly so he tested it on a scrap piece first. After it was apparent that drilling polycarbonate caused no problems, he continued to drill the rest of the pieces. To fit the arm and mounting blocks onto the bolt Jeremy had to file the holes to make them slightly larger. This allowed all the pieces to spin freely. He then cut a small strip of sheet metal and used it to securely mount the on board hydraulic syringe. Finally Jeremy cut a small piece of tubing and filled it with water so that he could test the arm.

At first construction was very simple as it only involved measuring and cutting materials. As the actual assembly of the arm took place more problems arose. With the help of the team many of these problems were overcome quite easily. The most difficult part, connecting the arm to the syringe, took multiple attempts. After cutting the brass connecting wires for the third time they finally fit into place. Jeremy also had trouble mounting the syringe to the polycarbonate. At first he used epoxy, seen in figure 2 below, but this broke off a few days later. To fix this he used sheet metal as a bracket which holds the syringe tightly in place.

Figure 2, hydraulic syringe being epoxied to mounting block.

Testing

While not all testing has been completed, major progress has been made. While mounting the arm onto the Rov frame Jeremy decided it would be beneficial to test the arm while there is plenty of time left. To do this he cut a short 3 foot section of tubing, the same that will be used in the tether. This was first attached to the onboard syringe and secured in place with the use of both epoxy, as a filler material, and a hot glue gun to ensure a seal. The tube was then filled with water, and 1/2oz of the syringe was filled. Extra care was taken to remove all of the air bubbles from the tube. The other end of the tube was stretched out and secured to the control station syringe. At first the arms movement was very stiff. A few simple adjustments of the bolt assemblies and this was fixed. The arm was extensively tested out of water in the hopes of finding faults that would only show after extended use. None were seen. The arm was then submerged in the test pools to test its performance underwater. The results were very encouraging as it seemed to work even better. The assembled arm and frame can be seen in Figure 3 below.

Figure 3, assembled Rov in test tank

There were multiple problems Jeremy had been expecting to occur. He was worried the arms would not close all the way, but taping the arms closed overnight stretched the brass wires enough to work correctly. Jeremy also feared that similar to the model, when the syringe would spin 90 degrees it would lock in place. Since he used a slightly different method of securing the wires this did not happen. The arm is now capable of working equally efficient no matter what position the syringe is in. A third problem was his worry that the arm would not close with enough force. After testing this does not seem to be a problem as the arm can hold about five pounds before the item slips. This will increase once the rubber grips are installed. The true limit on the weight the arm can hold will be determined by its effect on the stability of the frame. This cannot be tested until the entire Rov is complete.

Expectations

Although the arm is very near the point of completion, Jeremy still must work to make it meet his expectations. The arm, when completed must be able to hold about 3 pounds underwater and carry it to the surface. This must be done in a speedy fashion to score maximum points at the competition. He expects that my arm will be able to complete all the tasks without problem, although this must be tested to be certain. Jeremy’s hope is that the arm will function very smoothly at the competition and will not be the teams limiting factor, should there be one.

Mentor

Many of the major decisions Jeremy made were done with the help of his mentor. While not directly related to the field of hydraulics, my mentor, an electrician, was very helpful during construction. His personal shop was used to work on the more difficult pieces, while his connections to others in the field allowed him to find the answers to questions Jeremy had. The mentor is a close family friend and lives very near to Jeremy’s own home. This had made it convenient for him to share ideas with his mentor.

Conclusion

The Mates Rov project is a great learning experience that has taught Jeremy about teamwork and dedication. While designing the Rov Jeremy had to study the math and science related to the field of hydraulics and was able to gain a better understanding of their functions. As the competition nears, the amount of work completed as a team becomes apparent. Although it is too early to celebrate, Jeremy believes we have a good chance at winning the regional competition and moving on to the nationals. All testing so far has had nothing but positive results, and the arm is highly specialized to the contest tasks. The narrow design will prove useful in capturing the rock crabs, while the sturdy construction will make sure that minor bumps will not put the Rov out of commission. As a team they have high expectations of their designs and await the chance to prove ourselves in the upcoming competition.

For more details about the Rov team arm design on Sandy Hook, NJ, contact Jeremy Kuhn at jkuhn@mast.mcvsd.org, or visit http://www.se2rovarm.blogspot.com/.

Monday, February 4, 2008

Wednesday, January 16, 2008

Math and Science Calculations

The calculations used in determining the correct components for the hydraulic system are shown below. I needed a hydraulic system that would divide the force at the arm, as only a small force is needed compared to the usual forces used in hydraulic systems. Most hydraulic systems are used to gain a mechanical advantage, such as raising a car with a minimal amount of force. In the case of the Rov, a force of only 2 pounds is needed to clamp onto the heaviest object, and to safely secure it for a trip to the surface a force of 3 pounds would suffice. By examining Pascal’s principle I can prove that my design will function.

Force Required To Operate Arm:

One of the major concerns addressed in my presentations was a kink in the hydraulic line on my model. While a complete kink will cut off flow and make it difficult for the arm to function, minor bends and very long hydraulic lines have no effect. Pascals Equation P1=P2 proves that in a closed system the pressure at any point is equal to the pressure at all other points. Therefore by applying pressure at the control station, the pressure will be transmitted with full efficiency to the Rov arm. Since pressure equals force per unit area the following equation also holds true; F1/A1=F2/A2.

The master piston has a surface area of 1.227 square inches found by using the equation pi x r squared, or ((pi) x (.625)(.625)). The slave piston, found on the Rov, has a surface area of .785 square inches determined using the same formula, or ((pi) x (.5)(.5)). Since a force of 3 pounds is needed at the slave piston the previous equation can be used to determine the force required at the master piston.

F1/A1=F2/A2

(F1)/(1.227)=(3)/(.785)

(F1)/(1.227)=(3.8216)

(F1)=(1.227)x(3.8216)

F1= 4.6891

This equation proves that to deliver a force of 3 pounds at the Rov arm, a force of 4.6891 pounds must be applied at the control station. The airline tubing, which has the lowest maximum pressure rating of all the components, is capable of holding 22 psi. Therefore the system is capable of withstanding the 4.6891 pound force, and is capable of much more.

Distance Pistons Must Move:

Pascals Principle also states that that V1=V2, which means that the volume of fluid displaced on one side is equal to the volume of liquid that will appear on the other side. Since volume equals area x distance the following equation can be substituted. A1/D1=A2/D2. Since the areas have already been calculated, I can determine the distance we must depress the master piston to close the Rov arm. According to the current designs the arm will have to move a maximum of 1.8 inches to move the arm from a fully open position to a fully closed position.

A1=1.227” squared(master piston)

A2=.785” squared (slave piston)

D2= 1.8” ( distance moved by slave piston)

D1= ? (Distance the master piston is required to move)

A1/D1=A2/D2

(1.227) x (D1)=(.785) x (1.8)

(1.227) x (D1)=(1.413)

(D1)=(1.413)/(1.227)

(D1)=(1.1516)

D1= 1.1516”

This equation proves that to fully close the arm which requires the slave piston to extend 1.8 inches, seen in Figure 2, the master piston must be depressed 1.1516 inches, the same holds true when extracting the master piston to reopen the arm.

Figure 2 (Hydraulic Arm)

Mechanical Advantage:

By rearranging the previous equation, the mechanical advantage lost or gained by using a larger piston at the control station than the piston on the arm can be found. This equation is D1/D2=A2/A1=IMA.

D1=1.1516”

D2=1.8”

A2=.785” squared

A1=1.227” squared

IMA=? (Mechanical Disadvantage)

D1/D2=A2/A1=IMA

1.1516/1.8 = .785/1.227 =IMA

.6397=.6397 = IMA

This means that the mechanical advantage is .6397, since this number is less than one there is a disadvantage to using this system. This however was done purposefully to increase the closing speed of the robotic arm.

Math, Science, and Technology Analysis

My final solution for the Rov arm is a simple design that relies on the basic laws of hydraulics to function. Through calculations, seen on the attached document, I have determined the size of tubing and syringes I need to not just make my design functional, but also make it strong enough to complete the tasks. I also have decided to use polycarbonate sheeting for the main material to construct my arm.

Hydraulic System:

The original purpose of choosing hydraulics was to reduce the electricity needed by the entire Rov. After researching the laws and properties many more advantages became apparent. The main difference between hydraulics and pneumatics involves the tendency of the substance that fills the system to compress. A pneumatic system involves the use of air which can easily be compressed, thus requiring greater pressure to accomplish a task. In a hydraulic system the fluid, often oil, will not compress and therefore transfers all energy with very minimal loss. This also shows why it’s very important to remove all air from a hydraulic system. Due to the high efficiency of a hydraulic line there is almost no force lost to friction. This is defined by Pascals law which states “when there is an increase in pressure at any point in a confined fluid, there is an equal increase at every other point in the container.”(Pascals Principle), or defined by the equation P1=P2. Therefore a hydraulic tube can be led through all sorts of bends and over large distances without any sacrifice in performance.

My hydraulic system will also make use of force multiplication. At the control station I will use a 2oz syringe as the hydraulic pump, while a 1 oz syringe will be attached onto the arm. Force multiplication is determined by comparing the surface areas of the pistons. The equation to be used is pi * r^2. If piston B has a surface area 10 times greater than piston A, then any pressure applied to piston A will show up 10 times greater on piston B, although the distance the piston must travel will also be larger. This is shown in Figure 1 below with piston A being represented by F1 and piston B being represented by F2.

For my design I have divided the force rather than multiplied it. The main pressure will be applied by hand from the control station piston, called the master piston, and approximately two thirds of the force will be delivered to the piston on the Rov, called the slave piston. This also means that for every inch the master piston is depressed, the slave piston will extend 1.5652 inches. While it may seem odd that I am purposefully lowering the force delivered to the slave piston, it fits in context with the contest tasks. The maximum weight that must be lifted will be 2 pounds, although this is a stretch and the most likely weight will be closer to 1 pound or less. By decreasing the force I am making it harder for myself, or any other controller, to accidentally overload the arm. If too much pressure is applied the hydraulic system may simply break as it has only been designed according to the specifications of needing to hold a maximum weight of 5 pounds. The control line also is in danger of rupturing at a pressure greater than 22 psi.. I also believe that it will be more important to have a swift moving arm as it is unknown how stable the platform will be under water, and it may be necessary to quickly grab the objects rather than slowly clamp onto them. To apply a force of 3 pounds to pick up the heaviest contest object, the “black smoker rocks”, a force of 4.6891 pounds must be applied at the control station which is well within the capabilities of the system. This is explained on the attached calculations sheet.

Rov Arm Materials:

I have decided to use polycarbonate sheeting with a thickness of ½” as the main material in my design. It will be used to construct the arms as well as the top mounting block. The reason for this was the lightweight and impact resistant properties of the material. Polycarbonate has many other uses as well which show its strength. Polycarbonate is used to make bulletproof glass, shop safety goggles, and water bottles. It is also very easy to cut with a band saw. I had also considered using fiberglass but the initial cost of materials is nearly three times larger and it will require at least 3 days of extra construction time. Since my design only requires rectangular shapes and no intricate designs, this material seemed to be the best choice.

Conclusion:

Overall my design has shown through both a working model presented in class and calculations on the attached sheet that it is capable of completing the competition tasks. Using the laws of a closed hydraulic system I was able to void many of the concerns associated with my design. I believe that once constructed my final design will once again prove itself effective and complete all the required tasks.